Effective Thermal Management for Inverters

Inverters are key building parts in energy conversion. Thermal power losses in inverters occur during operation due to electrical resistance and switching losses in the semiconductor chips. The losses result from the conversion of direct and alternating current AC/DC. It is crucial to minimize these losses by transferring them to the heat sink in the best possible way to increase the overall efficiency.

Inverters

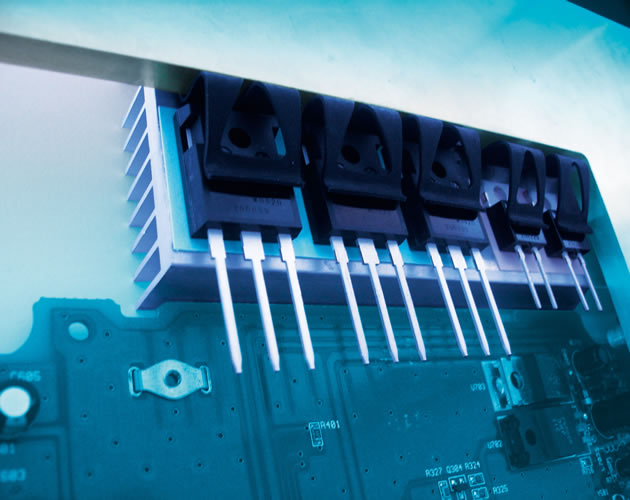

Inverters are built either from discrete components or with power modules. Typically, IGBTs and MOSFETs are used, and increasingly advanced SiC and GaN chips. The latter offer higher switching speeds and better power efficiency. However, they generate more heat, so even more efficient thermal management is required.

thermal conductive materials

For optimized heat flow, various thermal conductive materials can be used. These include thermal conductive pastes (TCP), phase change materials (PCM), ultra thermally conductive silicone-carbon films without dielectric insulation properties and thermally conductive insulating films such as thermosilicone films or PCM coated Kapton and polyimide films as well as thermally conductive silicone caps and sleeves with insulation properties. When designing-in electrical insulation films, attention must be paid to creepage distances and CTI in addition to thermal conductivity and insulation requirements.

HALA YOUR SPECIALIST

HALA specializes in thermal interface material (TIM) design-in and customized solutions. We believe that efficient thermal management further drives not only performance, but also sustainability of applications. Contact us to find out how we can improve your thermal management.

CONTACT

CONTACT